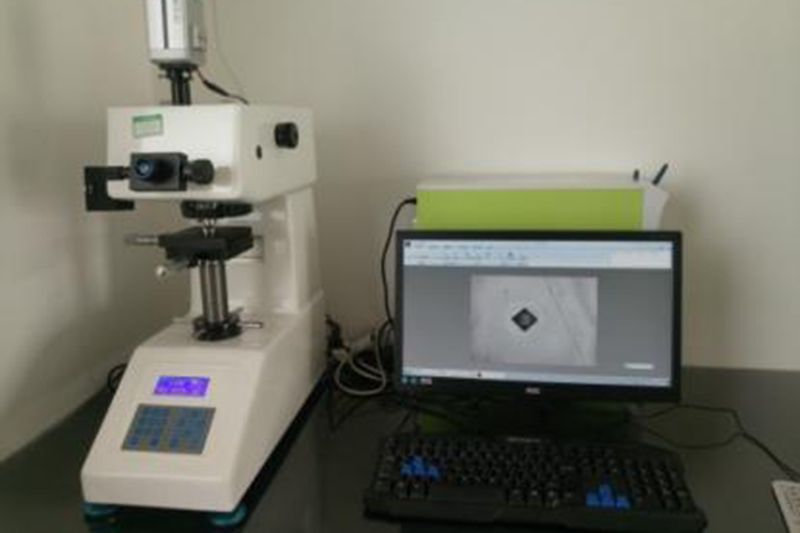

In our R&D center which was built in 2012, there are 5 expert researchers who have worked in the fields of casting, mold, extrusion, heat treatment and quality analysis for years. To accelerating scientific and technological progress, RH Group has changed the name of R&D center to testing and inspection center in 2017 and simultaneously partnered with third-party testing and inspection companies and universities for the development and scientific analysis of new materials and new technologies. Our testing and inspection center contains Italian GNR optical emission spectrometer, German ASCONA cross-sectional dimension measuring device, metallurgical microscope, digital Rockwell & Vickers hardness tester and other advanced testing devices, which enable us to carry out chemical composition analysis, mechanical properties testing, precision dimensional measuring, metallographic analysis and more services.

Quality Management System

ISO-9001:2015 Quality Management System

IATF16949:2016 Quality Management System

-

- Mold Designing

With sophisticated mold designing and mold opening capacities, RH Group successfully produced more than 100 thousands aluminum extrusions. We have four mold designers, two analysts and six experienced mold craftsman working as a team in designing and producing extrusion die that is specified.

-

- Raw Materials

RH Group is capable to process various aluminum profiles, ranging from 2000 series to 7000 series, allowing to manufacture aluminum alloys with high strength, high hardness and high resistance. We supply both aluminum tubes, bars of standard shapes, and also customized aluminum products in accordance with customer’s profiles.

-

- Extrusion

RH Group is equipped with 14 forward extrusion production lines, 2 backward extrusion production lines, 3 aluminum melting furnaces, 2 homogenizing furnaces, 4 straight drawing machines, 4 straightening machines, 1 quenching furnace, 5 aging furnaces, 3 diameter reducing machines, 1 centerless grinding machine, 2 polishing machines, 12 high precision sawing machines.