Aluminum Wire

With the experience of producing over 100 thousands aluminum extrusions, RH Group houses an extensive standard shapes die bank for mass production, thus to lower tooling costs. Being an aluminum extrusion manufacturer, RH Group can produce aluminum alloy rods in 2000, 3000, 4000,5000, 6000 and 7000 series, and deliver customized surface treatment and finishing service for our aluminum extrusions used in different applications, such as architecture, industry, electronics.

As an experienced aluminum extrusion service provider, our extruded aluminum wires can be offered with a variety of specifications as per your request.

RH Group can produce 2000 series to 7000 series aluminum wires, with diameter ranging from 4mm to 32mm. The maximum weight of a single aluminum wire can reach 300kg per coil.

Tempers: O/HXX/F

-

- Mold Designing

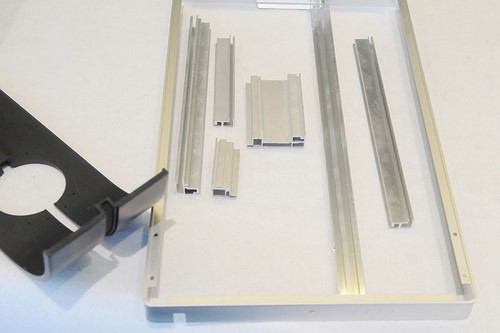

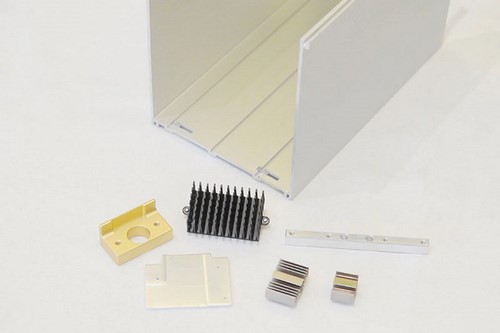

RH Group designed and opened dies over 100 thousand aluminum extrusions, including standard aluminum round tubes, aluminum rods, aluminum channels, and etc. RH Group supplies both custom extruded aluminum shapes and standard aluminum shapes, which saves customers’ tooling costs.

-

- Raw Materials

RH Group can process wide range of extrusion alloys for you to choose from, including 2007, 2011, 2014, 2017, 2024, 2618, 2A14, 2A50, 2A70,3003, 3004, 3A21, 4032, 4Y32, 5049, 5052, 5056, 5083, 5754, 5A02, 5A03, 5A05, 5A06, 5A12,6005, 6060, 6061, 6063, 6463, 6101, 6013, 6082, 6066, 6020, 6023, 6026, 6064, 6262,7001, 7003, 7005, 7020, 7021, 7022, 7026, 7046, 7050, 7055, 7068, 7075, 7A03, 7A04, etc.

-

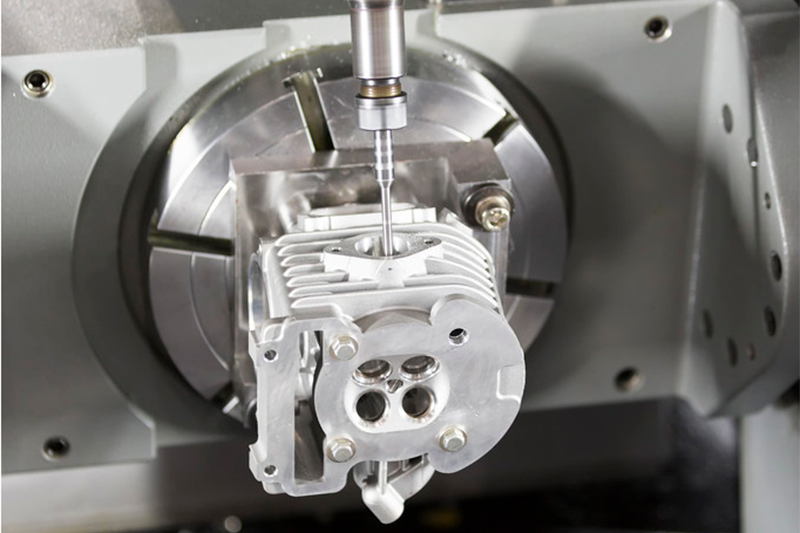

- Extruding and Precision Processing

RH Group is fully equipped with 16 extrusion lines and 180 units of CNC cutting machines, 270 units of CNC machinery tools, etc., able to implement the entire chain through every processing stages, from extrusion die designing, material selection and smelting, aluminum profile extruding, cutting, surface treatment (polishing, brushing, anodizing, electroplating), precision parts processing, assembling, packing and delivering.

-

- Quality Control

RH Group is capable to deliver chemical composition analysis, mechanical properties testing and metallographic analysis towards aluminum profiles. We are equipped with GNR’s OES (Optical Emission Spectrometers) from Italy, ASCONA’s optical profile measuring system from Germany, metalloscope, digital Vickers Hardness Tester, Rockwell apparatus and other advanced testing equipment.