RH Group is equipped with 14 forward extrusion production lines, 2 backward extrusion production lines, 3 aluminum melting furnaces, 2 homogenizing furnaces, 4 straight drawing machines, 4 straightening machines, 1 quenching furnace, 5 aging furnaces, 3 diameter reducing machines, 1 centerless grinding machine, 2 polishing machines, 12 high precision sawing machines. With annual output of 600T-3600T for each production line, RH Group’s 18 production lines enable a total yearly output of 60000T and more.

- billet heating

- peeling

- extrusion

- stretching

- saw cutting

- annealing

- cold heading

- cold drawing

- quenching

- straightening

- age hardening

- finished part saw cutting

- packaging

-

-

-

2200T Backward Extrusion Production Line Backward extrusion, also known as indirect extrusion, offers reduced extrusion load, high extrusion speed, and allows for processing longer metal billet; The billet being extruded features a cross section that is uniform over the entire length of the metal extrusion.

-

-

- Surface Treatment

RH Group is capable to offer aluminum profiles undergone various surface treatment services, including polishing, drawing, anodizing, electroplating, sand blasting, dusting, etc. Different treatment services are optional according to different circumstances with different industries, humidities and PH values.

-

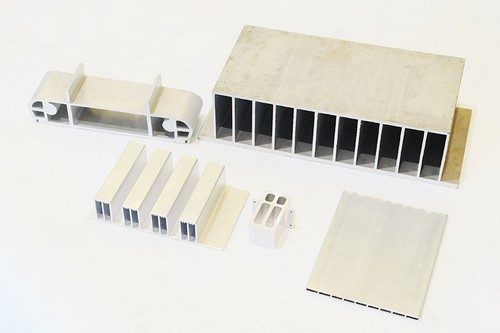

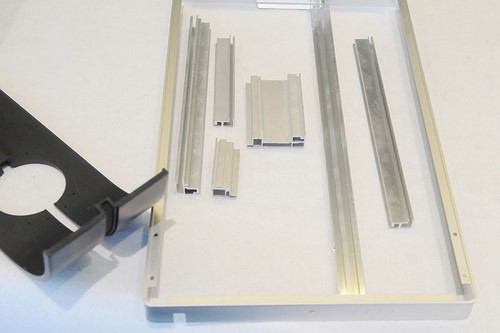

- Precision Processing

RH Group has 130 precision cutting machines, wire-cut discharge machines and 270 CNC machine tools, allowing strong precision processing capacity for various customized precision parts, such as aerospace aluminum parts, automotive parts, laboratory apparatus parts, medical equipment parts, etc.

-

- Quality Control

In our R&D center which was built in 2012, there are 5 expert researchers who have worked in the fields of casting, mold, extrusion, heat treatment and quality analysis for years.