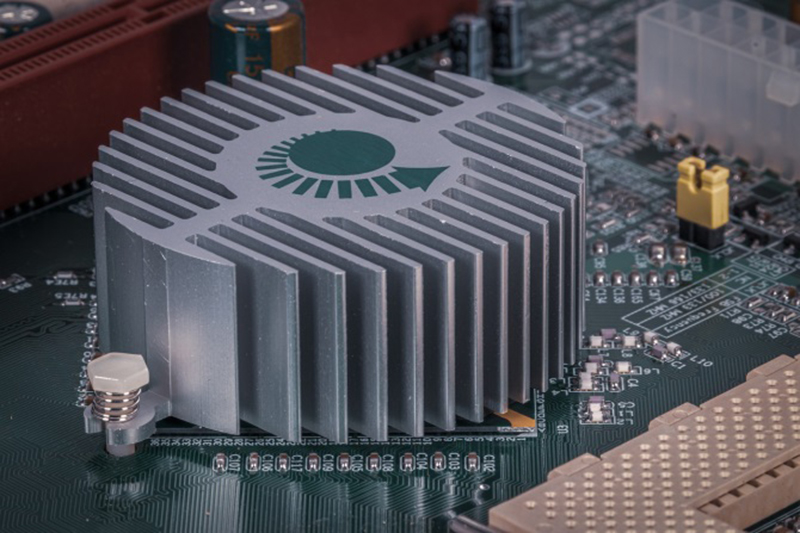

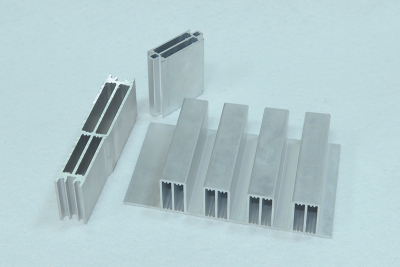

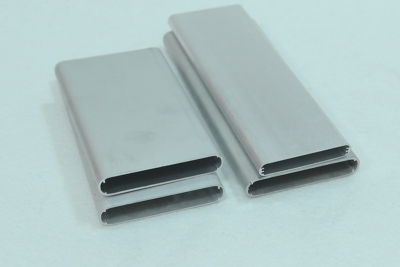

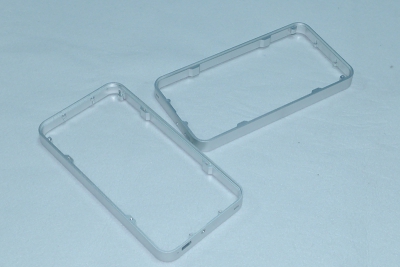

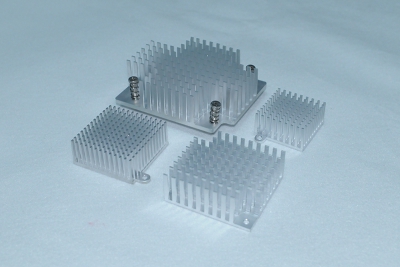

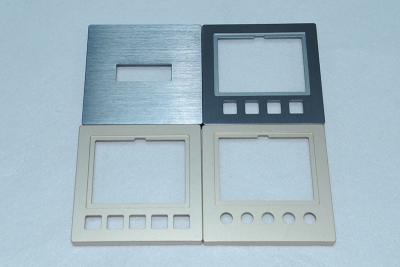

The reason that aluminum extrusions are becoming more prevalent in electrical and electronic appliances is aluminum's properties of low density, light weight, excellent surface treatability, low cost and multi variety of types which can satisfy individual production demands. RH Group offers aluminum extrusions which can be used for computer heat sink, access control & time attendance device, TV frame, speaker enclosure, etc.

- Light weight for easy installation and transportation; At the same performance of heat dissipation, the weight of aluminum heat sink is only one eleventh of the cast iron heat sink, one sixth of the steel heat sink and one third of the copper heat sink;

- Aluminum extensions can be made into various shapes and specifications; Due to the large and uniform cross section of extruded aluminum heat sink, the process of assembly and surface treatment can be carried out in one pass while allowing for direct on-site installation, thus greatly lowering the cost for installation and maintenance; In addition to the high durability, extruded aluminum heat sink is processable with various surface treatments to meet specific application needs;

- A heat sink made from extruded aluminum can withstand high pressure; Even it is designed with very thin fins, the extruded aluminum heat sink can also withstand loads of pressure, bending, pulling and impaction, avoiding from damaging during transportation, installation and usage;

* We supply your industry with our aluminum solutions

-

- Mold Designing

With sophisticated mold designing and mold opening capacities, RH Group successfully produced more than 100 thousands aluminum extrusions. We have four mold designers, two analysts and six experienced mold craftsman working as a team in designing and producing extrusion die that is specified.

-

- Raw Materials

RH Group is capable to process various aluminum profiles, ranging from 2000 series to 7000 series, allowing to manufacture aluminum alloys with high strength, high hardness and high resistance. We supply both aluminum tubes, bars of standard shapes, and also customized aluminum products in accordance with customer’s profiles.

-

- Extrusion

RH Group is equipped with 14 forward extrusion production lines, 2 backward extrusion production lines, 3 aluminum melting furnaces, 2 homogenizing furnaces, 4 straight drawing machines, 4 straightening machines, 1 quenching furnace, 5 aging furnaces, 3 diameter reducing machines, 1 centerless grinding machine, 2 polishing machines, 12 high precision sawing machines.

-

- Surface Treatment

RH Group is capable to offer aluminum profiles undergone various surface treatment services, including polishing, drawing, anodizing, electroplating, sand blasting, dusting, etc. Different treatment services are optional according to different circumstances with different industries, humidities and PH values.

-

- Precision Processing

RH Group has 130 precision cutting machines, wire-cut discharge machines and 270 CNC machine tools, allowing strong precision processing capacity for various customized precision parts, such as aerospace aluminum parts, automotive parts, laboratory apparatus parts, medical equipment parts, etc.

-

- Quality Control

In our R&D center which was built in 2012, there are 5 expert researchers who have worked in the fields of casting, mold, extrusion, heat treatment and quality analysis for years.