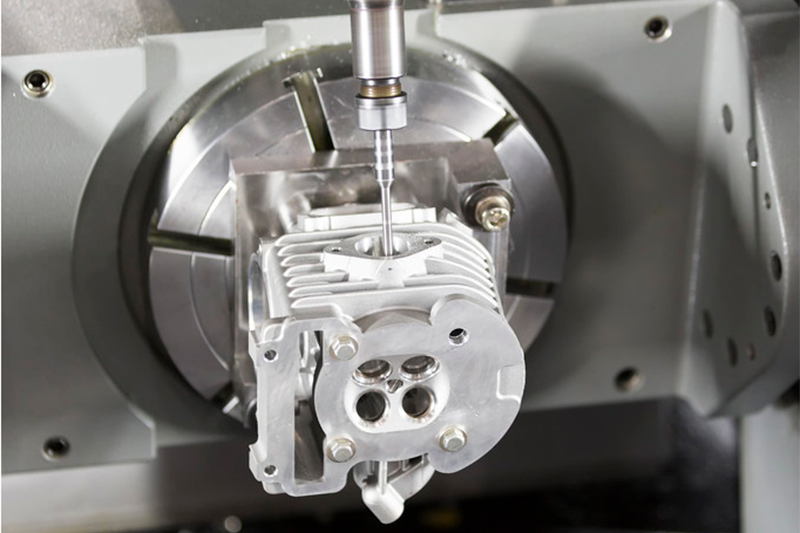

RH Group has 130 precision cutting machines, wire-cut discharge machines and 270 CNC machine tools, allowing strong precision processing capacity for various customized precision parts, such as aerospace aluminum parts, automotive parts, laboratory apparatus parts, medical equipment parts, etc.

In CNC machining process, there is a movement path, known as tool path, where cutting tool will take as it moves along the path from starting point and ultimately backs to the initial point. The tool path not only involves the cutting path, but also when the tool is not cutting but travelling.

Benefits- High stability, high precision and high repeatability, in compliance with the requirements of aircraft components manufacturing;

- High production efficiency when multi variety and small batch production is required, CNC machining can shorten the time for production preparation, machine adjustment and inspection, significantly reducing the cycle time with optimal output;

- Capable of processing complex surfaces that are difficult to handle by common methods, even those surfaces are invisible to the naked eye;

-

- Quality Control

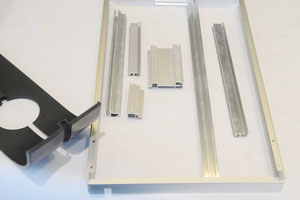

In our R&D center which was built in 2012, there are 5 expert researchers who have worked in the fields of casting, mold, extrusion, heat treatment and quality analysis for years.

-

- Packaging and Delivering

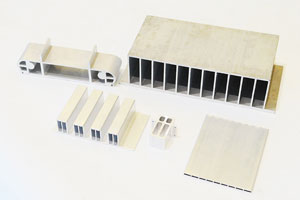

RH Group has five subsidiaries and its factory covers an area of 120,000 m², able to produce a yearly output of 60,000T aluminum profiles. Therefore, RH Group has adequate production capacity for large orders.

-

- Mold Designing

With sophisticated mold designing and mold opening capacities, RH Group successfully produced more than 100 thousands aluminum extrusions. We have four mold designers, two analysts and six experienced mold craftsman working as a team in designing and producing extrusion die that is specified.