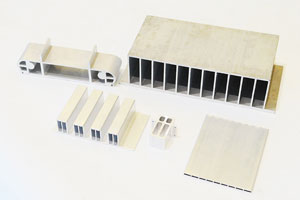

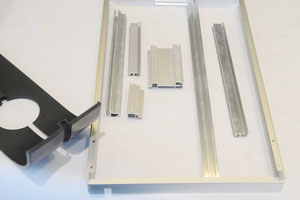

RH Group offers various customized aluminum extrusions with different profile sections, including channel, tubing, bar , plate and any shaped aluminum extrusion by dies. We also provide extrusion forming, CNC machining, electric discharging and other precision processing methods, together with polishing, drawing, anodizing, electroplating and other surface treatment services, thus to produce aluminum extrusions of different applications, such as aluminum parts and frames for any projects and machinery.

| Series | Model |

| 2000 Series | 2007,2011,2014,2017,2024,2618,2A14,2A50,2A70,etc. |

| 3000 Series | 3003, 3004, 3A21,etc. |

| 4000 Series | 4032, 4Y32, etc. |

| 5000 Series | 5049, 5052, 5056, 5083, 5754, 5A02, 5A03, 5A05, 5A06, 5A12,etc. |

| 6000 Series | 6005, 6060, 6061, 6063, 6463, 6101, 6013, 6082, 6066, 6020, 6023, 6026, 6064, 6262, etc. |

| 7000 Series | 7001, 7003, 7005, 7020, 7021, 7022, 7026, 7046, 7050, 7055, 7068, 7075, 7A03, 7A04, etc. |

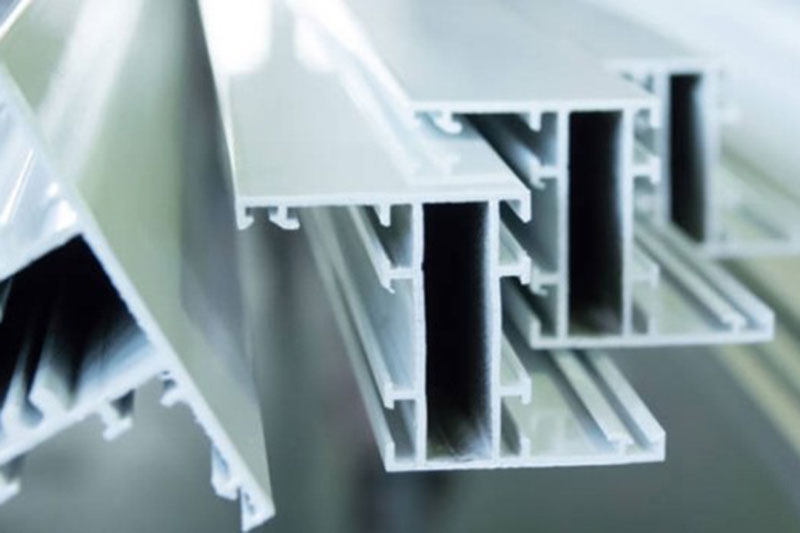

Extrusion is a versatile manufacturing process that allows for a wide range of shapes. Based on your drawings, a die is created which matches the cross-sectional shape of your profiles.

The alloy of your choice is loaded onto an extrusion press and forced through the die by a powerful ram. It emerges in the appropriate shape, is mechanically pulled along a runout table while being cooled with air or water, and is sawed to table length.

It is allowed to cool further and then is mechanically stretched into alignment. It is then ready for heat treatment and fabrication operations such as machining or surface finishing.

- RH Group provides tailor-made aluminum extrusions when customers offer specific alloy material, accurate drawings and aluminum profile finishing requirements.

- Extrusion die processing service, no matter free or paid, is available in RH Group as long as design drawing or requirements are supplied from customers.

- Certain order quantity leads to favorable price. RH Group will start the production and offer in-time delivery service in accordance with order requirements.

- No extra fees will be charged except the special packing and transportation costs due to customer’s requirements. RH Group will deliver aluminum extrusion packaging with experienced packaging way if no special wishes from customers.

-

- Mold Designing

With sophisticated mold designing and mold opening capacities, RH Group successfully produced more than 100 thousands aluminum extrusions. We have four mold designers, two analysts and six experienced mold craftsman working as a team in designing and producing extrusion die that is specified.

-

- Raw Materials

RH Group is capable to process various aluminum profiles, ranging from 2000 series to 7000 series, allowing to manufacture aluminum alloys with high strength, high hardness and high resistance. We supply both aluminum tubes, bars of standard shapes, and also customized aluminum products in accordance with customer’s profiles.

-

- Extrusion

RH Group is equipped with 14 forward extrusion production lines, 2 backward extrusion production lines, 3 aluminum melting furnaces, 2 homogenizing furnaces, 4 straight drawing machines, 4 straightening machines, 1 quenching furnace, 5 aging furnaces, 3 diameter reducing machines, 1 centerless grinding machine, 2 polishing machines, 12 high precision sawing machines.

-

- Surface Treatment

RH Group is capable to offer aluminum profiles undergone various surface treatment services, including polishing, drawing, anodizing, electroplating, sand blasting, dusting, etc. Different treatment services are optional according to different circumstances with different industries, humidities and PH values.

-

- Precision Processing

RH Group has 130 precision cutting machines, wire-cut discharge machines and 270 CNC machine tools, allowing strong precision processing capacity for various customized precision parts, such as aerospace aluminum parts, automotive parts, laboratory apparatus parts, medical equipment parts, etc.

-

- Quality Control

In our R&D center which was built in 2012, there are 5 expert researchers who have worked in the fields of casting, mold, extrusion, heat treatment and quality analysis for years.