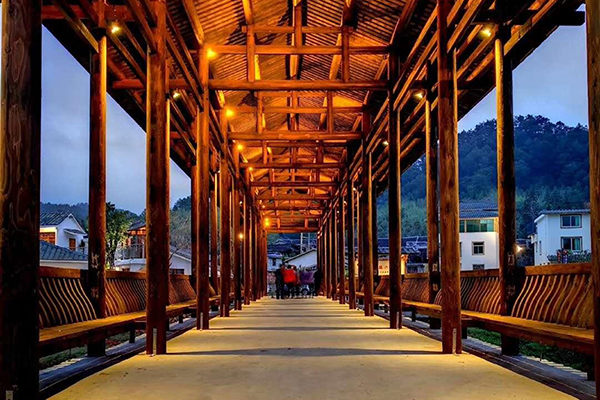

RH Group has adaptable solutions of aluminum extrusions for your lighting applications, particularly in projects such as flood lighting, landscape lighting, facade lighting, indoor lighting, etc. In addition to the common aluminum extrusions for lighting applications, we can also supply custom extruded aluminum products to accommodate your specific requirements for lighting fixture.

With rich years of experience in execution of a multitude of lighting projects, RH Group knows that the quality of aluminum profile plays a critical role in lighting projects, especially those projects associated with high-altitude installation. Therefore, all aluminum extrusions we supplied for lighting fixtures are undergone through strict quality inspection process.

* We supply your industry with our aluminum solutions

-

- Mold Designing

With sophisticated mold designing and mold opening capacities, RH Group successfully produced more than 100 thousands aluminum extrusions. We have four mold designers, two analysts and six experienced mold craftsman working as a team in designing and producing extrusion die that is specified.

-

- Raw Materials

RH Group is capable to process various aluminum profiles, ranging from 2000 series to 7000 series, allowing to manufacture aluminum alloys with high strength, high hardness and high resistance. We supply both aluminum tubes, bars of standard shapes, and also customized aluminum products in accordance with customer’s profiles.

-

- Extrusion

RH Group is equipped with 14 forward extrusion production lines, 2 backward extrusion production lines, 3 aluminum melting furnaces, 2 homogenizing furnaces, 4 straight drawing machines, 4 straightening machines, 1 quenching furnace, 5 aging furnaces, 3 diameter reducing machines, 1 centerless grinding machine, 2 polishing machines, 12 high precision sawing machines.

-

- Surface Treatment

RH Group is capable to offer aluminum profiles undergone various surface treatment services, including polishing, drawing, anodizing, electroplating, sand blasting, dusting, etc. Different treatment services are optional according to different circumstances with different industries, humidities and PH values.

-

- Precision Processing

RH Group has 130 precision cutting machines, wire-cut discharge machines and 270 CNC machine tools, allowing strong precision processing capacity for various customized precision parts, such as aerospace aluminum parts, automotive parts, laboratory apparatus parts, medical equipment parts, etc.

-

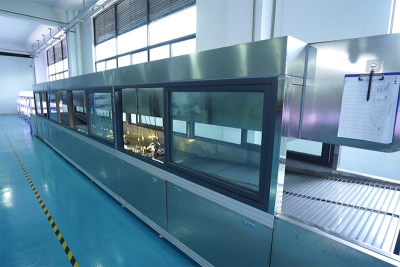

- Quality Control

In our R&D center which was built in 2012, there are 5 expert researchers who have worked in the fields of casting, mold, extrusion, heat treatment and quality analysis for years.

Our precision manufacturing department has over 100 employees, half of them work for assembly, quality control and packaging in the workshop, greatly increasing the work efficiency.

We have dozens of craftsman working in light fixture production lines to guarantee our stable and high productivity per day. Simultaneously they adopt a variety of precision testing and measuring equipment to ensure all our products are GB4208-2017 compliant.